20.6.2024 | Robit® Extreme Carbide

Enhanced wear properties in hard and abrasive rock conditions

Increase your drilling productivity with Robit Extreme Carbide.

- Increase the bit lifetime!

- Improve the rate of penetration!

- Extend the grinding interval!

Robit® Extreme Carbides have been designed to provide the best performance and lifetime in hard and abrasive rock conditions. Extreme Carbide has hard outer layer and an optimized core with improved resistance to breakages.

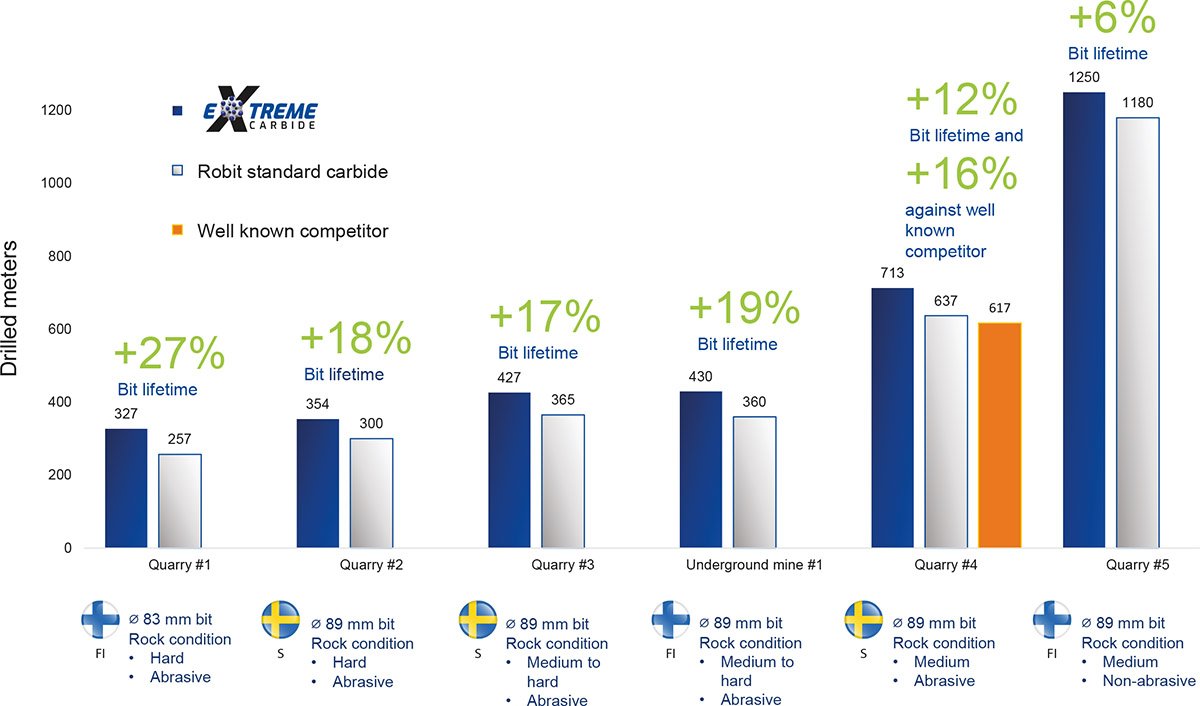

- Increased bit lifetime up to 30% in hard and abrasive rock conditions

- Carbides will stay sharper for longer time providing efficient drilling performance

- Faster rate of penetration (ROP)

- Less grinding needed especially at the start of the bit lifetime

- Sharper bit will save your drill string => less recoil energy to rods and shanks

Robit recommends to regrind the Extreme carbides for optimal drilling performance.

Proven performance of the Extreme Carbide

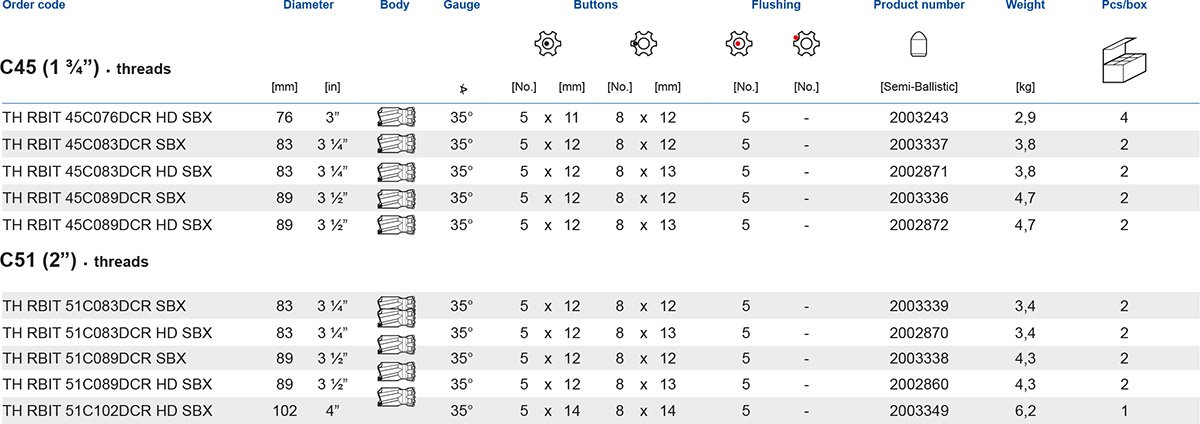

Robit® Extreme Carbide Rbit™ Selection

Download the brochure: